Cutting Fluid Leading Brand: Mecom MCM Plant-Based Cutting Fluid Supersol Mg - the Preferred Choice

Jun 13, 2023Mecom MCM Plant-Based Cutting Fluid Supersol Mg demonstrates outstanding performance in the machining of magnesium alloys AZ91D and AZ31B materials, particularly in terms of resistance to hard water, reduced generation of magnesium build-up on machines, and strong anti-oxidation capabilities.

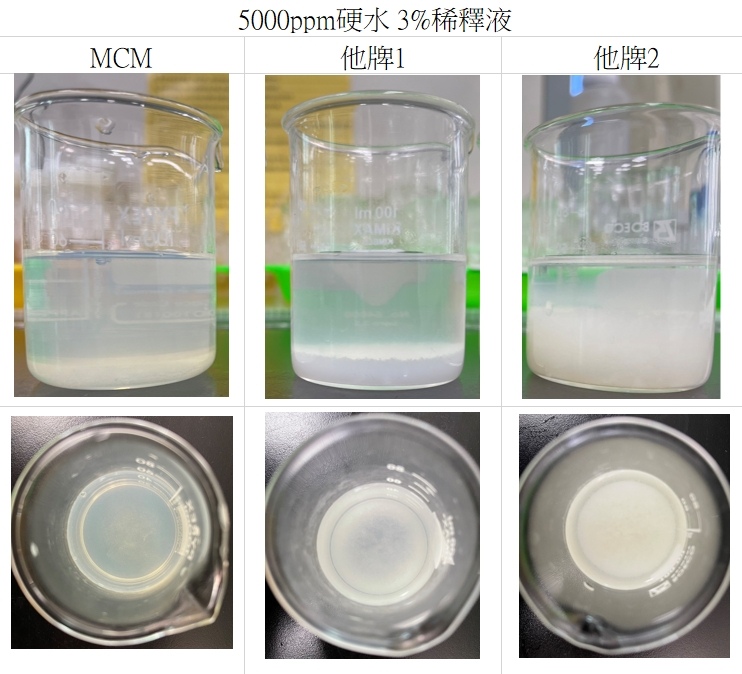

- Mecom MCM Plant-Based Cutting Fluid Supersol Mg exhibits exceptional resistance to hard water when used in the machining of magnesium alloys AZ91D and AZ31B materials. Hard water contains a high concentration of calcium, magnesium, and other ions that can react with the components of cutting fluid, forming insoluble precipitates that can affect the performance and stability of the cutting fluid. However, Mecom MCM Plant-Based Cutting Fluid Supersol Mg, through the addition of special ingredients and additives, effectively withstands the impact of hard water, maintaining the lubrication and cooling properties of the cutting fluid. This allows for consistent machining results even in environments with hard water, enhancing processing quality and efficiency.

- Mecom MCM Plant-Based Cutting Fluid Supersol Mg exhibits a resistance to the formation of magnesium oxides when used in the machining of magnesium alloys AZ91D and AZ31B materials. Magnesium oxides are insoluble compounds that can adhere to the surfaces of cutting tools and workpieces, increasing friction and wear, which, in turn, affect machining quality and tool lifespan. The components and additives within Mecom MCM Plant-Based Cutting Fluid Supersol Mg are effective at suppressing the formation of magnesium oxides, preventing oxidation reactions when the cutting fluid comes into contact with magnesium alloys. Consequently, the cutting fluid maintains its lubrication and cooling properties, reduces tool wear, extends tool life, and enhances machining efficiency.

- Mecom MCM Plant-Based Cutting Fluid Supersol Mg possesses robust antioxidation capabilities. When used in the machining of magnesium alloys AZ91D and AZ31B materials, cutting fluids are susceptible to oxidation, which can lead to a decline in their performance and the formation of magnesium oxide saponification products, subsequently impacting machining quality. The antioxidative components within Mecom MCM Plant-Based Cutting Fluid Supersol Mg effectively suppress the occurrence of oxidation reactions, preserving the stability and performance of the cutting fluid. This not only extends the cutting fluid's service life, reducing replacement frequency and costs but also enhances machining stability and consistency.

In summary, Mecom MCM Plant-Based Cutting Fluid Supersol Mg exhibits excellent characteristics in the machining of magnesium alloys AZ91D and AZ31B, including resistance to hard water, a reduced tendency to form magnesium soaps, and strong antioxidation capabilities. These attributes make Mecom MCM Plant-Based Cutting Fluid Supersol Mg an ideal choice for cutting fluids in magnesium-aluminum alloy machining. It enhances machining efficiency, extends tool life, and has a lesser impact on the environment and operators. As demands for environmental-friendliness and sustainable development continue to rise, Mecom MCM Plant-Based Cutting Fluid Supersol Mg will play an increasingly crucial role in machining magnesium alloys AZ91D and AZ31B materials.

Here are the actual comparative test results for magnesium alloy antioxidation and hard water resistance: